Air Blow Fans (ABF) is more than just a company – we’re a community. Innovation and discovery are at the heart of everything we do, constantly driving us to foster a culture of learning and growth. Recently, we embarked on a project with two mechanical engineering master’s students from the University of Pretoria, Justin Smith and Alex Brocco.

Their research projects are being brought to life through a fan we’ve crafted specifically for them. This fan is more than a machine; it’s a symbol of our commitment to progress and a testament to the power of collaboration.

Justin Smith’s project, “Vibration-based condition monitoring methods for fault detection of fan systems”, and Alex Brocco’s project, “A hybrid-model-based condition monitoring approach for an axial fan using blade tip timing and casing pressure measurements with transfer learning model calibration”, are set to contribute to early fault detection in the fan industry.

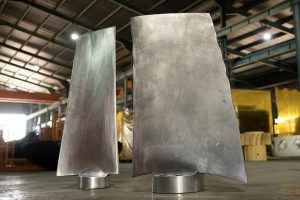

In a first-of-its-kind initiative, the fans are equipped with sensors to monitor the blades. These axial fan prototypes, based at our factory in Springs and larger than those typically built in labs, are designed for experimental purposes and will not be used in real-world situations. The students will conduct a series of tests on these fans to collect valuable data on a full-scale industrial fan.

These will include aerodynamic tests, cutting a blade (to simulate a blade crack) to observe the impact, adding mass to the blades to alter the natural frequency, and even intentionally damaging the bearing to see if the monitoring system can detect the errors.

Bernard Viviers, Control & Instrumentation Engineer at ABF, emphasised the benefits of the fans and the research. “The primary goal is data collection, which will help us enhance fan diagnostics moving forward.

In essence, this project is about more than just improving fan performance. It’s about harnessing the power of data to predict and prevent future failures, enhancing the technology used for fan diagnostics, and, ultimately, creating a safer and more efficient industry.”

Gavin Ratner, ABF’s Managing Director, highlighted the mutual benefits of this partnership. “This is our first time working directly with students, but it certainly won’t be the last. We see great value in collaborating with universities, as it fosters innovation and helps prepare the next generation of engineers for real-world challenges.”

We’re inspired by this project’s potential and its impact on the future of engineering and mining ventilation. We’re not just building fans; we’re creating a legacy and shaping the future of the industry.